Durrant Pate/Contributor

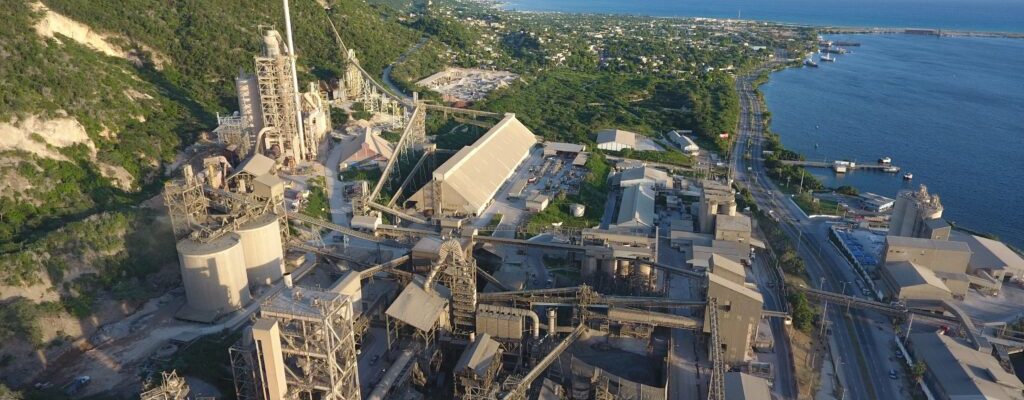

Jamaican cement manufacturer is making significant progress in its environment and safety performance during the March quarter.

Of note is that phase one of Carib Cement’s expansion project, which will further reduce its carbon emissions and deliver an increase of up to 30 per cent in cement production, is progressing as scheduled for full completion next year. This project will help its ultimate parent company, Cemex, headquartered in Mexico to reach its ambitious sustainability consolidated targets of reduced CO2 emissions.

This is being done through the optimisation of heat consumption during the cement production process, minimising the company’s carbon footprint in Jamaica. Additionally, Carib Cement has commissioned the XRC3000c shredder obtained from the Austria-based industrial manufacturer, UNTHA.

This powerful shredder has been further supporting our sustainability efforts, enabling us to effectively shred used tyres sourced from the Riverton landfill in Kingston and other materials such as pallets to be used as alternative energy sources in the cement-making process. The company also continued to advance activities under its dust mitigation plan to capture and reduce fugitive dust.

No lost time incidents

Turning to health and safety, the East Kingston-based company is reporting that there were no lost time incidents recorded during the first quarter of 2024. This success is mainly due to the dedication of Carib Cement’s workforce to safety and the company’s ongoing training and development, and rigid monitoring initiatives.

Through rigorous engagement with modules such as the health and safety re-induction programme, first aid recertification courses, fire warden training, and emergency drill exercises, the management team continuously contributes to fortifying the company’s health and safety protocols and practices. These modules are integral mechanisms for the transformation, enrichment, and sustenance of the company’s safety-centric work cult ure.

Comments